What is On-Site Tooling?

Tooling is a critical aspect of injection molding. It is a big initial investment and needs designed and built properly in order to meet the part specifications during production. Additionally, if the tooling is not correct, modifications are costly and time-consuming!

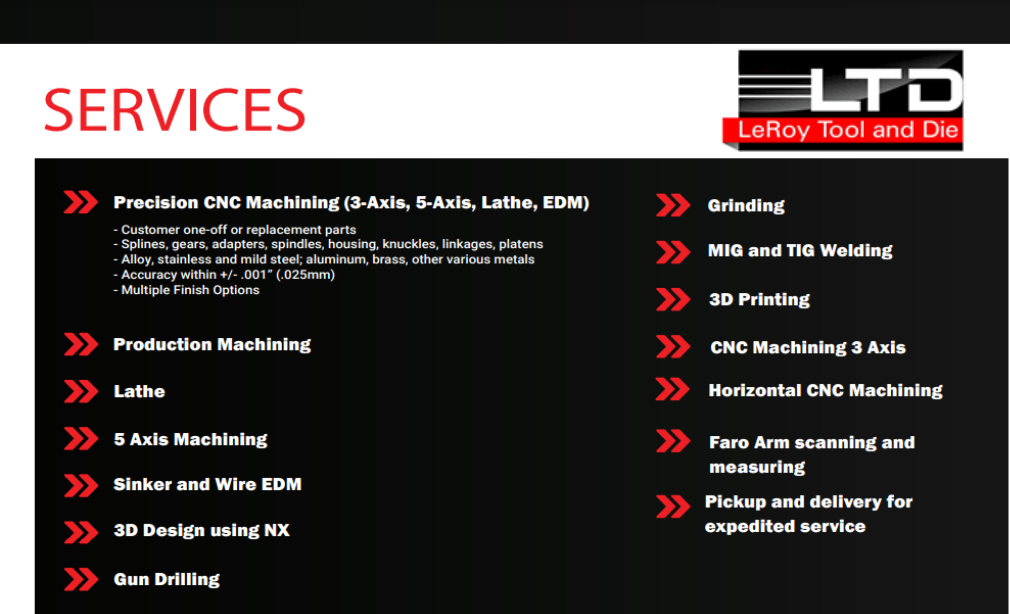

Northern Molding is located on-site and shares ownership with LeRoy Tool & Die, which can then become an extension of the production process, providing customers with an on-site complete manufacturing solution. This provides value by minimizing the number of vendors involved and enhances speed-to-market.

Our unique layout and business model provides streamline manufacturing which results in a more cost-efficient process that saves time and money!